close

Choose Your Site

Global

Social Media

Views: 222 Author: Rebecca Publish Time: 2026-02-04 Origin: Site

Content Menu

● What Is HPMC and Why Dissolution Matters

● Key Factors Influencing HPMC Dissolution in Water

● How HPMC Behaves in Cold and Hot Water

● Method 1: Cold Water Dispersion (Recommended for Most HPMC Grades)

>> Practical steps for cold water dispersion

● Method 2: Hot Water Dispersion Followed by Cooling

>> Typical hot water dispersion procedure

● Method 3: Dry Powder Premixing Method

>> How the dry premix method works

● Method 4: Organic Solvent Wetting and Dissolution

>> Typical organic solvent wetting process

● Special Case: Instant HPMC vs Non‑Instant HPMC

● Practical Tips to Avoid Clumps When Dissolving HPMC in Water

● How HPMC Viscosity Grade Affects Dissolution

● Role of Temperature and pH in HPMC Dissolution

● Common Application Scenarios for HPMC Dissolution in Water

● Typical Problems When Dissolving HPMC in Water and How to Solve Them

● How to Choose the Right Dissolution Method for Your HPMC

● FAQ About How To Dissolve HPMC in Water

>> 1) What is the best water temperature to dissolve HPMC?

>> 2) Why does HPMC form lumps or “fisheyes” when mixed with water?

>> 3) How can I dissolve HPMC in water without clumps in a large‑scale batch?

>> 4) Can I premix HPMC with other powders to improve its dissolution in water?

>> 5) Is hot water suitable for dissolving all types of HPMC?

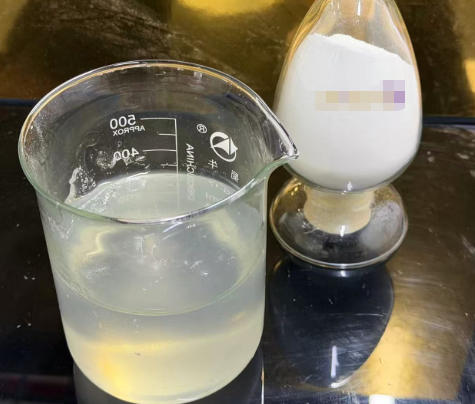

HPMC (hydroxypropyl methylcellulose) dissolves in water smoothly when you control water temperature, dispersion, and stirring speed instead of simply dumping the powder into water. Proper HPMC dissolution avoids clumps, ensures full hydration, and helps your final product achieve stable viscosity, workability, and appearance.

HPMC is a nonionic, water‑soluble cellulose ether widely used in building materials, coatings, detergents, food, pharmaceuticals, and personal care formulations. When HPMC is poorly dissolved in water, it easily forms soft gel lumps that trap dry powder inside, causing dosing errors, viscosity instability, and performance defects in mortars, putties, tile adhesives, detergents, and gels.

HPMC also shows thermoreversible gelation: it dissolves in cold water but tends to form a reversible gel at higher temperatures depending on the grade. Understanding this behavior is essential to choosing the right method to dissolve HPMC in water and to avoid unnecessary processing problems.

Several factors directly affect how HPMC dissolves in water and how fast a clear, lump‑free solution or dispersion can be obtained.

- Water temperature: HPMC generally dissolves in cold or room‑temperature water, while hot water above its gel temperature forms a reversible gel instead of a true solution.

- HPMC grade type: Instant (surface‑treated) HPMC is designed for rapid dispersion in cold water, while non‑surface‑treated HPMC grades rely more on hot‑water dispersion plus cooling.

- Particle size and bulk density: Finer HPMC particles wet more easily but may agglomerate more quickly if added too fast and without proper dispersion.

- Agitation: Moderate, continuous stirring helps separate HPMC particles and promote uniform hydration; excessive shear during early dispersion may push particles together and create larger lumps.

- Additives and formulation: Salts, surfactants, organic solvents, and co‑thickeners can either promote wetting and dispersion or slow hydration, depending on concentration and system design.

- HPMC concentration: Higher HPMC concentrations increase viscosity and may slow down hydration and dissolution, especially for higher‑viscosity HPMC grades.

To understand how to dissolve HPMC in water, it is important to look at its solubility behavior at different temperatures.

In cold water (roughly 10–30 °C), HPMC typically disperses first and then gradually hydrates to form a clear or slightly turbid colloidal solution. During this process, HPMC particles swell as water penetrates the polymer chains, and viscosity builds over time until full hydration is reached. This behavior allows better control during mixing and reduces the risk of sudden gel formation.

In hot water (above about 60–70 °C, depending on HPMC grade), HPMC becomes insoluble and forms a reversible gel. When the hot HPMC–water system is cooled back down below the critical temperature, the gel network collapses, and HPMC can re‑dissolve to form a solution again. This thermoreversible gelation is widely used in hot‑water dispersion methods, where HPMC is first dispersed in hot water and then dissolved during cooling.

HPMC is also soluble in many water–organic mixed solvents and certain polar organic solvents such as methanol, ethanol, isopropanol, and acetone, which is useful for organic solvent wetting methods. In most industrial applications, however, water remains the main solvent phase for dissolving HPMC.

Cold water dispersion is the most common and generally recommended method to dissolve HPMC in water for many instant and cold‑water‑soluble grades. This method is suitable for a wide range of industrial HPMC types, especially surface‑treated grades used in construction materials, detergents, and personal care products.

- Prepare a clean mixing tank or container with about 60–70% of the total water at a temperature around 20–25 °C (and usually below 40 °C).

- Start slow to medium agitation to form a gentle vortex in the water.

- Gently sprinkle HPMC powder into the vortex in a controlled, continuous manner rather than dumping the entire amount at once.

- Continue stirring for 10–20 minutes until HPMC is uniformly dispersed, giving a slurry or slightly thickened dispersion without large floating agglomerates.

- Add the remaining water to reach the target volume while maintaining agitation, if the process design requires dilution.

- Allow the mixture to stand for additional time, often 30–60 minutes or more, so HPMC can complete hydration and develop the final viscosity profile.

Cold water dispersion minimizes premature gel formation and gives each HPMC particle time to absorb water separately. This method is suitable for most construction HPMC, detergent HPMC, and cosmetic HPMC systems that use cold‑water‑instant products.

Hot water dispersion followed by cooling is ideal for many non‑surface‑treated HPMC grades that do not disperse easily in cold water alone. These HPMC grades are nearly insoluble in hot water but dissolve when the system cools down, which can be used to achieve even distribution before hydration begins.

- Heat part or all of the water (commonly 80–90 °C, sometimes around 70–85 °C depending on HPMC grade) in a mixing vessel.

- Start stirring and gradually add HPMC powder into the hot water; HPMC particles usually float initially and then form a uniform gel‑like slurry without developing full viscosity.

- Continue stirring until HPMC is evenly dispersed in the hot water and no large lumps remain.

- Add cold water or ice water to the slurry or simply cool it down with continuous stirring until the temperature drops to around 20–40 °C.

- As the temperature falls below the HPMC gel point, the gel layer collapses, water penetrates the particles, and HPMC gradually dissolves to form a clear or translucent solution.

This hot water dispersion plus cooling method takes advantage of the thermoreversible gel properties of HPMC to achieve uniform distribution before hydration. It is common in construction, coatings, and other industrial systems where process equipment can handle heated water and controlled cooling.

The dry powder premixing method is especially useful when HPMC is part of a dry‑mix formulation such as putty powder, tile adhesive, gypsum‑based mortar, self‑leveling compounds, or other dry‑blend building materials. In these products, HPMC is dry‑mixed with cement, fillers, and other additives, then water is added on site.

- Pre‑blend HPMC powder with cement, calcium carbonate, gypsum, or other powders in a high‑efficiency mixer until HPMC is evenly distributed at a low concentration throughout the mixture.

- When the dry mix is used, add water while stirring; because each tiny “unit” of the mixture contains only a small amount of HPMC, the polymer is exposed to water in a more diluted and dispersed form.

- As mixing continues, HPMC disperses and dissolves without forming large gel lumps, and the mortar or putty gradually reaches the specified consistency and workability.

This method prevents HPMC from clumping because the polymer is never added as a dense powder layer on the water surface. It is a standard technique for industrial producers of HPMC‑based dry mortars, plasters, tile adhesives, and joint fillers.

In some formulations, especially where surfactants, oils, or solvent blends are involved, HPMC can be pre‑wetted with organic solvents or oils before contacting water. HPMC is insoluble in many pure organic solvents but can be swelled and separated, then dissolved once water is added.

- Select a suitable solvent such as ethanol, ethylene glycol, propylene glycol, or a compatible oil already present in the formula, and mix HPMC powder with this solvent to create a uniform wet premix.

- The solvent coats and separates HPMC particles, preventing them from instantly hydrating as a single mass when they later meet water.

- Add water to the premix under stirring, allowing the solvent–water mixture to penetrate and hydrate HPMC gradually until it dissolves completely.

This method is particularly useful for HPMC applications in coatings, oil‑containing cosmetic systems, emulsions, and some liquid detergents where direct cold‑water dispersion is difficult or leads to excessive foaming.

Instant or surface‑treated HPMC is manufactured to disperse quickly in cold water and then gradually hydrate, providing a delayed viscosity build. Non‑surface‑treated HPMC, by contrast, usually requires more careful hot water dispersion or controlled cold water dispersion to achieve lump‑free solutions.

For instant HPMC:

- Add the HPMC slowly to cold water under moderate stirring and allow sufficient time for viscosity to develop after dispersion.

- Avoid adding instant HPMC directly into hot water above its gel temperature, which can cause gel clumps and incomplete dissolution.

For non‑instant HPMC:

- Prefer hot water dispersion followed by cooling, or use dry premixing with other powders to improve wetting and dissolution.

- In some special processes, both hot‑water dispersion and organic solvent wetting are combined to obtain optimal HPMC performance.

Choosing the right HPMC grade and matching it with the correct dissolution method will simplify processing and stabilize product performance. When closing a supply contract or developing a new HPMC‑containing formulation, it is recommended to confirm whether the HPMC is instant or non‑instant and to request detailed dissolution recommendations from the manufacturer.

Formulators working with HPMC often struggle with fisheyes and clumps when making solutions or dispersions. Several practical measures can greatly reduce this risk and improve overall solution quality.

- Always add HPMC gradually: Sprinkle HPMC onto the water surface instead of dumping it in a single pile, so each particle gets contact with water.

- Control agitation: Use consistent, moderate stirring that pulls powder into the water while preventing air entrainment and vortex collapse; very high speed at the beginning can actually push particles together.

- Use pre‑mixing: For construction and detergent applications, pre‑blend HPMC with salts, fillers, or other powders to decrease local concentration and make HPMC easier to wet.

- Respect water temperature windows: Stay below the gel temperature for cold dispersion or clearly above it for the hot‑dispersion‑cooling method, and avoid working in an intermediate temperature zone where partial gelation and clumping are most likely.

- Allow sufficient hydration time: Even when HPMC looks dispersed, viscosity may continue to rise as full hydration is reached, so plan an adequate holding time into your process.

- Choose the right HPMC viscosity grade: High‑viscosity HPMC needs a longer time to dissolve and hydrate than low‑viscosity grades; selecting the appropriate viscosity can improve production efficiency.

By combining these tips with the correct HPMC grade selection, you can produce stable, lump‑free HPMC solutions that are easy to pump, apply, or fill, with reproducible viscosity and performance.

The viscosity grade of HPMC (for example 50 cps, 400 cps, 4000 cps and above) strongly influences dissolution time and solution handling. Low‑viscosity HPMC typically dissolves and hydrates faster than high‑viscosity HPMC because its molecular chains are shorter and easier for water to penetrate.

In practice, a low‑viscosity HPMC grade may fully dissolve in about 15–30 minutes under proper mixing conditions. Higher‑viscosity HPMC grades can require significantly longer hydration times, especially at higher concentrations or lower water temperatures. When designing a production process, it is important to align the chosen HPMC viscosity grade with the available mixing time, tank design, and target viscosity of the final product.

For applications such as self‑leveling mortars or very fluid coatings, lower‑viscosity HPMC can simplify dissolution, while for tile adhesives and joint fillers, high‑viscosity HPMC is often preferred for its strong thickening and water retention, even if the dissolution time is longer.

Temperature is not the only parameter influencing how HPMC dissolves in water; pH also plays an important role in certain systems. HPMC is generally stable and soluble over a wide pH range, often from about pH 3 to pH 11, which covers most practical applications in construction, detergents, and personal care.

Although HPMC itself is nonionic and does not ionize like typical polyelectrolytes, extreme pH values can impact the stability of the base formulation and any co‑additives, indirectly affecting HPMC behavior. Mildly neutral conditions (around pH 6–8) are commonly used in many HPMC solutions for optimal stability and skin compatibility, especially in cosmetic and personal‑care products.

Temperature and pH should therefore be monitored together: both excessively high temperature and very extreme pH can cause instability, loss of performance, or undesirable interactions with other formulation components. When optimizing a process to dissolve HPMC in water, it is good practice to keep temperature and pH within the recommended ranges for the specific HPMC grade and application.

Different industries use slightly different protocols for dissolving HPMC in water, based on equipment, batch size, and final product requirements.

- Construction mortars and putties: HPMC is usually dissolved via dry premixing in powdered formulations, then hydrated during water addition at the job site, ensuring improved workability, water retention, and open time.

- Tile adhesives and grouts: HPMC is part of the dry‑mix formula; when contractors add water, HPMC dissolves in situ and provides sag resistance, slip resistance, and enhanced adhesion.

- Detergents and cleaners: HPMC is dispersed in cold water or in water–surfactant systems, sometimes with salt premix or surfactant premix methods, to rapidly build viscosity without lumps or fisheyes.

- Coatings and adhesives: HPMC may be dissolved using cold water or hot water dispersion plus cooling, depending on grade and solvent composition, to provide thickening, leveling, and film‑forming properties.

- Food, pharmaceutical, and cosmetic gels: HPMC is usually dissolved in purified water at controlled temperature and pH, often using cold‑water dispersion to obtain transparent or translucent gels with reproducible viscosity.

In each case, the underlying principle is the same: properly disperse HPMC in water or water–solvent systems, then allow controlled hydration to complete dissolution.

Even when the general method is correct, users sometimes encounter specific problems when dissolving HPMC in water.

- Persistent floating powder: This often occurs when HPMC is added too quickly or when the surface of the water is not agitated enough. Slowing down the feeding and increasing surface turbulence usually solves this.

- Gel lumps that never disappear: These lumps are typically caused by local over‑concentration and immediate gelation. Using the dry premix method, organic solvent wetting, or a two‑stage hot‑then‑cold method can help.

- Very slow viscosity build: This can result from low water temperature, insufficient hydration time, or an HPMC grade that is not optimized for the specific process. Raising water temperature (within the safe cold range) and increasing mixing time often improves the rate.

- Foam formation during mixing: High agitation and surfactant‑rich systems can introduce foam that traps air bubbles. In such cases, using defoamers, optimizing agitation speed, and adjusting HPMC addition points are helpful.

By analyzing these common problems and adopting targeted solutions, formulators can make the process of dissolving HPMC in water more stable, efficient, and predictable.

Choosing the best way to dissolve HPMC in water depends on several practical questions:

- Is the HPMC instant or non‑instant?

- Is the formulation prepared as a liquid product or a dry blend?

- What mixing equipment and temperature‑control capabilities are available?

- What viscosity grade and concentration of HPMC are required?

For liquid formulations with instant HPMC and limited heating capacity, cold water dispersion is usually the simplest and most reliable option. For dry‑mix building materials, the dry powder premixing method is almost always the standard solution. For non‑instant HPMC or special solvent systems, a combination of hot water dispersion and organic solvent wetting can be used.

By answering these questions and working closely with an experienced HPMC supplier, you can select a dissolution method that fits your process, minimizes waste, and improves final product performance.

Dissolving HPMC in water successfully depends on understanding both the polymer's cold‑water solubility and its thermoreversible gel behavior at higher temperatures. By choosing between cold water dispersion, hot water dispersion plus cooling, dry powder premixing, or organic solvent wetting, you can consistently obtain smooth, lump‑free HPMC solutions for construction, detergents, coatings, and many other applications. Matching the HPMC grade to the proper dissolution method and following good agitation, dosing, temperature, and hydration practices will help you achieve stable viscosity, reliable performance, and efficient production in every HPMC‑based formulation.

For most cold‑water‑soluble HPMC grades, the best water temperature is typically room temperature, around 20–25 °C, and generally below 40 °C. At these temperatures, HPMC can disperse and hydrate without triggering gelation that leads to clumping. For hot‑water‑dispersion methods, water is heated to about 70–90 °C first to create a gel‑like dispersion, then cooled back to near room temperature to complete dissolution.

HPMC forms lumps when the outer layer of the powder hydrates too fast, creating a soft gel shell that traps dry material inside. As a result, water cannot easily penetrate into the center of these gel particles, leaving undissolved HPMC cores that appear as fisheyes or clumps in the solution. Adding HPMC too quickly, using insufficient stirring, or working at an unfavorable temperature often increases the risk of lump formation.

To dissolve HPMC in water without clumps at large scale, start by precisely controlling the powder feeding rate and water vortex, making sure HPMC is sprinkled slowly into well‑agitated water. Use cold‑water dispersion for instant HPMC, and hot‑water dispersion plus cooling or dry premixing for non‑instant grades, depending on your system. Industrial mixers, in‑line dispersion equipment, or powder induction systems can further improve HPMC wetting and minimize manual handling errors.

Yes, premixing HPMC with other dry materials is one of the most effective ways to improve dissolution and prevent agglomeration. In dry‑mix mortars, putties, and similar products, HPMC is blended with cement, gypsum, fillers, and additives so that each portion of the mix contains only a small amount of HPMC, which dissolves more easily when water is added. This dry powder premixing method is widely used in the construction industry to ensure consistent HPMC performance and easy on‑site mixing with water.

Hot water alone is not suitable for directly dissolving all HPMC types, because HPMC is practically insoluble in hot water above its gel temperature. However, hot water is very useful for dispersion: many non‑instant HPMC grades are first dispersed in hot water, forming a gel‑like slurry that later dissolves as the mixture cools down. Instant HPMC, on the other hand, is designed mainly for cold‑water dispersion, and direct addition into hot water can cause severe lumping and incomplete dissolution.