close

Choose Your Site

Global

Social Media

Views: 222 Author: Rebecca Publish Time: 2026-02-12 Origin: Site

Content Menu

● What Is Hydroxypropyl Methylcellulose (HPMC)?

● Key Properties of HPMC That Matter in Formulation

>> Functional Performance Summary

● How Is HPMC Chemically Structured?

● Main Applications of HPMC by Industry

>> 1. Construction and Building Materials

>> 2. Pharmaceuticals and Nutraceuticals

>> 4. Coatings, Paints, and Adhesives

>> 5. Personal Care and Household Products

● HPMC vs Other Cellulose Ethers (HEMC, HEC)

● Is HPMC Safe? Regulatory and Toxicological Overview

● Practical Guidelines: How to Use HPMC in Formulations

● Latest Trends: HPMC in Sustainable and High‑Performance Formulations

● Why Work With a Professional HPMC, HEMC, and HEC Manufacturer?

● FAQs About Hydroxypropyl Methylcellulose (HPMC)

>> 1. What is hydroxypropyl methylcellulose (HPMC) used for?

>> 2. Is HPMC safe to use in food and pharmaceuticals?

>> 3. How does HPMC improve construction mortars?

>> 4. What is the difference between HPMC and HEMC or HEC?

>> 5. How should HPMC be added to formulations to avoid lumping?

Hydroxypropyl methylcellulose (HPMC), also known as hypromellose, is a semi‑synthetic, water‑soluble cellulose ether used as a thickener, water‑retention agent, film‑former, binder, and stabilizer in construction materials, pharmaceuticals, food, coatings, and personal care products.

Derived from purified plant cellulose, HPMC is chemically modified with methyl and hydroxypropyl groups, giving it excellent solubility, biocompatibility, and versatility across many industries.

HPMC is produced by etherifying natural cellulose so that some of the hydroxyl groups on the glucose units are replaced with methoxy and hydroxypropoxy groups.

This chemical substitution disrupts the crystalline structure of cellulose, making HPMC hydrophilic, cold‑water soluble, and capable of forming clear, stable solutions or gels.

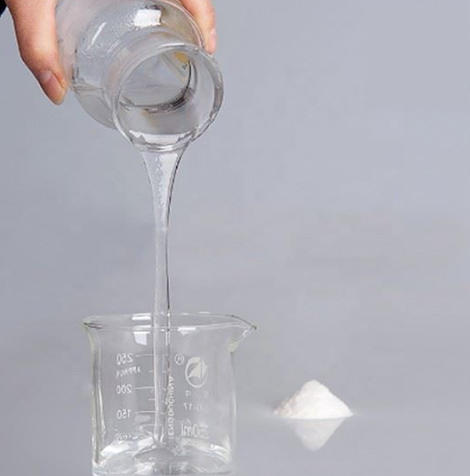

In commercial form, HPMC is usually a white or off‑white, odorless, tasteless powder that dissolves in cold water to form transparent or slightly opalescent solutions of various viscosities.

By adjusting the degree of substitution and polymerization, manufacturers can tailor HPMC grades for different performance requirements in construction, pharmaceuticals, food, and daily chemicals.

HPMC performance is determined by several core functional properties that formulators rely on across industries.

- High water solubility in cold water, forming clear solutions.

- Strong thickening ability over a wide viscosity range.

- Excellent water‑retention performance in porous systems such as cement and gypsum.

- Good film‑forming ability, yielding transparent, flexible films with barrier properties.

- Useful emulsifying and stabilizing behavior in emulsions and suspensions.

- Surface activity that improves wetting and dispersion of pigments and fillers.

- Biocompatibility, low toxicity, and a favorable environmental profile.

| HPMC property | What it means in practice | Typical applications |

|---|---|---|

| Water solubility | Easily dissolves in cold water, stable solutions | Dry‑mix mortars, tablets, food systems |

| Viscosity and thickening | Precise rheology control, improved body | Tile adhesive, wall putty, sauces, creams |

| Water retention | Slows water loss, improves hydration and curing | Cement and gypsum mortars, plasters |

| Film‑forming | Transparent, flexible films, barrier functions | Tablet coatings, edible films, coatings |

| Emulsifying and stabilizing | Stable emulsions and suspensions | Creams, lotions, food emulsions |

| Biocompatibility | Safe contact with tissues, low irritation | Ophthalmic gels, oral solid dosage forms |

For product designers, these properties allow HPMC to act simultaneously as a rheology modifier, protective colloid, binder, and functional film former, reducing the need for multiple separate additives.

At the molecular level, HPMC is built on a cellulose backbone composed of D‑glucose units linked by β‑1,4‑glycosidic bonds.

Each glucose unit has three reactive hydroxyl groups that can be substituted with methoxy (–OCH₃) and hydroxypropoxy (–OCH₂CHOHCH₃) groups through an etherification reaction.

The degree of substitution and molar substitution determine the balance between hydrophilicity, gelation behavior, and thermal properties.

By adjusting these parameters, manufacturers create HPMC grades with different solubility profiles, gel temperatures, and viscosities suited to construction powders, controlled‑release matrices, or food textures.

In construction, HPMC is one of the most important cellulose ethers used in dry‑mix mortars and other cement‑based systems.

Common uses include:

- Tile adhesives and grouts, improving open time, slip resistance, and workability.

- Cement and gypsum plaster, renders, and skim coats, providing water retention and sag resistance.

- Self‑leveling underlayments and floor screeds for flow control and segregation resistance.

- Exterior and interior wall putty for easy troweling and crack reduction.

In these systems, HPMC:

- Retains water in mortar, allowing complete hydration and reducing shrinkage cracks.

- Enhances workability, giving a creamy, easy‑troweling consistency.

- Improves adhesion to substrates and overall mechanical strength when properly formulated.

HPMC is a key pharmaceutical excipient used for both solid oral forms and ophthalmic preparations.

Typical applications include:

- Tablet binder and disintegrant in direct compression and wet granulation.

- Hydrophilic matrix former for sustained‑release tablets, controlling drug release profiles.

- Film‑coating polymer for tablets and pellets, improving appearance and stability.

- Hard capsule shells as a vegan alternative to gelatin for vitamins and supplements.

- Ophthalmic gels and artificial tears as a lubricating, viscosity‑enhancing agent.

These uses rely on HPMC biocompatibility, its ability to swell and form gels, and its stable performance across pH ranges commonly encountered in the gastrointestinal tract and ocular surface.

In food, HPMC (E464) is used as a multifunctional additive.

Key roles include:

- Thickener and stabilizer in sauces, dressings, and beverages.

- Emulsion stabilizer and foam stabilizer in products like whipped toppings and desserts.

- Fat replacer and bulking agent in reduced‑fat foods and bakery products.

- Film former in edible coatings, contributing to moisture and oil barriers.

In these applications HPMC helps achieve pleasant textures, stable emulsions, and extended shelf life.

In coatings and water‑based paints, HPMC serves as a thickener, emulsifier, film‑former, and stabilizer.

Benefits include:

- Improved viscosity control and leveling, reducing sagging and brush marks.

- Better pigment dispersion and suspension stability during storage.

- Enhanced adhesion and wear resistance of the final film.

Similar functions apply in water‑based adhesives and sealants, where HPMC helps balance open time, tack, and final bond strength.

HPMC is also widely used in shampoos, body washes, creams, gels, and household cleaners.

Typical contributions:

- Viscosity control and suspension of insoluble active ingredients.

- Pleasant rheology, including non‑dripping, easy spreading behavior in gels and lotions.

- Stability and clarity in surfactant‑rich formulations.

Its mildness and low irritation profile are important advantages for leave‑on and rinse‑off products.

Formulators often compare HPMC with hydroxyethyl methylcellulose (HEMC) and hydroxyethyl cellulose (HEC) when selecting the best cellulose ether for a given application.

| Feature | HPMC | HEMC | HEC |

|---|---|---|---|

| Main substituents | Methyl and hydroxypropyl | Methyl and hydroxyethyl | Hydroxyethyl only |

| Solubility | Cold‑water soluble, thermally gelling | Cold‑water soluble, thermally gelling | Cold‑water soluble, no strong thermal gelation |

| Typical uses | Construction, pharmaceuticals, food, coatings | Construction mortars, EIFS, paints | Paints, personal care, detergents |

| Key strengths | Balanced water retention, film‑forming, release control | High water retention, good workability at low temperature | Excellent thickening and clarity in surfactant systems |

In construction, HPMC and HEMC often appear together, with fine tuning of grade and dosage used to optimize water retention and workability under different climate conditions.

In detergents and personal care products, HEC is frequently selected for its clarity and compatibility, while HPMC may be used when film‑forming or special rheology is needed.

Global regulatory agencies generally regard HPMC as safe when used within established guidelines in food, pharmaceuticals, and cosmetics.

- In food, HPMC is approved as additive E464 in many markets and is commonly used in processed foods.

- Toxicological studies show low acute and chronic toxicity, good biocompatibility, and no clear evidence of carcinogenicity at typical use levels.

- In pharmaceuticals, HPMC has been used as an excipient and matrix former for controlled‑release dosage forms for decades.

As with any ingredient, sensitive individuals may experience mild gastrointestinal discomfort or intolerance, but such cases are uncommon relative to the widespread use of HPMC in consumer products.

For manufacturers, the main safety tasks are ensuring high purity, controlling residual solvents and by‑products, and complying with relevant pharmacopeial or food‑grade standards.

Correct hydration and dispersion of HPMC are critical to achieving consistent performance.

Typical best practices include:

1. Premix HPMC powder with other dry ingredients such as cement, fillers, pigments, or sugar to improve wetting and avoid lumping.

2. Add water gradually under adequate agitation so that the polymer hydrates evenly.

3. Allow sufficient time for full viscosity development, which may require a maturation period after initial mixing.

4. Control temperature, as HPMC solutions can exhibit thermal gelation, especially at higher substitution levels.

5. Select the correct viscosity grade so that final application rheology is appropriate for spraying, brushing, troweling, or pouring.

In construction dry‑mix mortars, for example, a small difference in HPMC viscosity or substitution can significantly affect open time, anti‑sagging behavior, and troweling performance, so lab evaluation and field trials are essential.

Recent research highlights HPMC role in sustainable materials, advanced drug delivery, and high‑performance coatings.

- In pharmaceuticals, HPMC is widely used in hydrophilic matrices for controlled release and is being studied for more sophisticated drug delivery systems.

- In food and packaging, HPMC‑based films offer biodegradable, transparent coatings with moderate moisture and oxygen barrier properties.

- In construction, there is growing interest in optimizing HPMC grades for low‑VOC, energy‑efficient building materials and compatibility with supplementary cementitious materials.

These trends reinforce HPMC position as a key polymer for next‑generation formulations that need both performance and sustainability.

For construction, pharmaceutical, food, and personal care formulators, partnering with a specialized cellulose ether manufacturer is essential to ensure consistent quality and reliable technical support.

A professional producer of HPMC, HEMC, and HEC can offer:

- Stable quality control on viscosity, substitution, particle size, and moisture.

- Tailor‑made grades for specific applications such as tile adhesive, self‑leveling compounds, tablet coatings, or food systems.

- Technical guidance on formulation optimization, mixing procedures, and troubleshooting.

- Regulatory documentation for pharmaceutical, food, and construction compliance requirements.

For buyers and R&D teams, this cooperation directly impacts product performance, production efficiency, and the ability to respond quickly to market demands for new or improved formulations.

If you are developing or upgrading construction mortars, pharmaceutical dosage forms, food systems, or personal care products, choosing the right HPMC grade is critical to success.

Contact our technical team with your application details, target viscosity, and processing conditions so we can recommend optimized HPMC, HEMC, or HEC solutions, arrange sample evaluations, and support you from laboratory formulation to full‑scale industrial production.

Contact us to get more information!

HPMC is used as a thickener, water‑retention agent, film‑former, binder, and stabilizer in construction materials, pharmaceuticals, food, coatings, and personal care products.

Its versatility comes from its ability to dissolve in water, control viscosity, and interact compatibly with many other ingredients.

Yes, HPMC is widely accepted as safe in food and pharmaceutical applications when used within established regulatory limits.

In pharmaceuticals, it has a long history of use as an excipient in tablets, capsules, and ophthalmic preparations.

In cement and gypsum mortars, HPMC improves water retention, workability, open time, and adhesion, while reducing sag and the risk of cracking.

It helps maintain a uniform moisture profile during setting and curing, which enhances final mechanical properties and surface quality.

HPMC carries methyl and hydroxypropyl groups, HEMC has methyl and hydroxyethyl groups, and HEC has only hydroxyethyl substitution.

These structural differences affect solubility, thermal gelation, and application focus, with HPMC widely used in construction, pharmaceuticals, and food, HEMC favoring construction and coatings, and HEC often used in paints and personal care.

The most common approach is to premix HPMC with other dry ingredients or disperse it in a non‑solvent medium before adding water under strong agitation.

Allowing sufficient hydration time and controlling temperature helps the polymer fully develop viscosity and ensures a smooth, lump‑free system.

1. https://www.kimacellulose.com/characteristics-and-applications-of-hydroxypropyl-methylcellulose.html

2. https://www.kimachemical.com/news/detailed-explanation-of-hpmc-chemical-composition/

3. https://www.kimacellulose.com/how-to-use-hydroxypropyl-methylcellulose-hpmc.html

4. https://www.hpmc.com/recommend-products/hpmc-cellulose.html

5. https://www.chemicalbook.com/article/what-is-hydroxypropyl-methyl-cellulose.htm

6. https://www.ihpmc.com/news/safety-of-hpmc-in-food-additives/

7. https://www.sciencedirect.com/topics/chemistry/hydroxypropyl-methylcellulose

8. https://pmc.ncbi.nlm.nih.gov/articles/PMC12196896/

9. https://www.pharmaexcipients.com/news/hpmc-key-excipient/